Articles

Join the Cortex Success Story!

Instructions for Use

The Evolution of Dental Implants: From Primitive Tooth Substitutions to Biomimetic Masterpieces

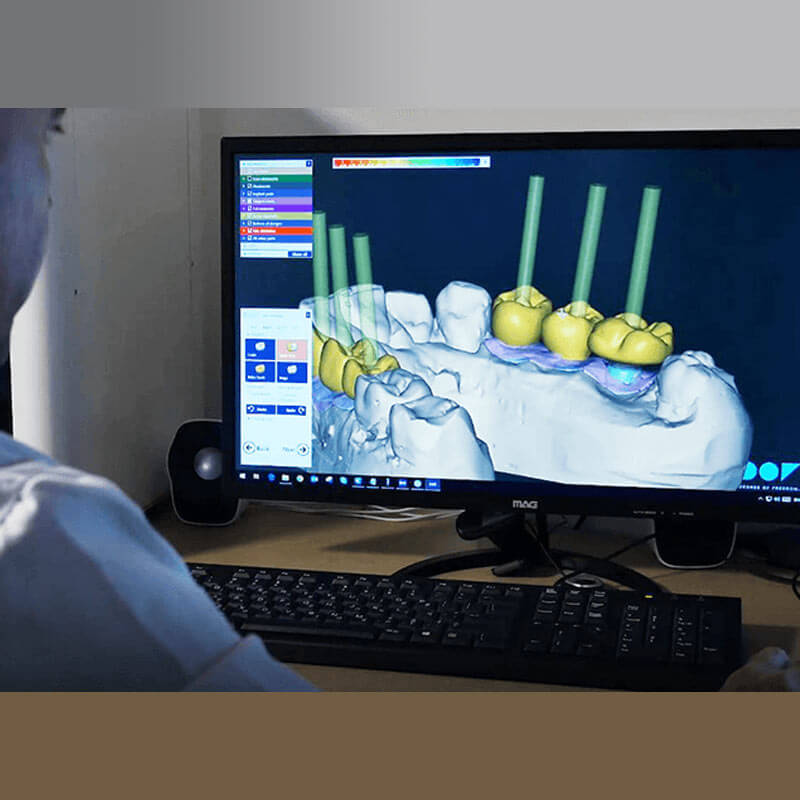

Dental Scan

The integration of 3D scanning technologies into implant dentistry over the last decade marks a pivotal shift from traditional methodologies to digitally-driven precision. Intraoral optical scanning, in particular, has become an essential tool in the armamentarium of dental professionals, enabling the capture of highly detailed and accurate representations of a patient’s oral anatomy.

The Digital Revolution in Dental Implantology

In today’s fast-paced world, the field of dentistry is experiencing a technological transformation, especially in the area of dental implantology. This digital shift is setting new standards in treatment accuracy, efficiency, and patient and practitioner experience. The most striking innovations are evident in the process of dental implants, where digital advancements are making significant strides.

Advanced 3D radiographic imaging has taken the place of traditional dental impressions and X-rays.

The Transformation of Implant Planning through Digital Technology

In the field of dental implantation, accuracy is crucial for success. Recent technological advancements have revolutionized this area. Today, digital systems enable dentists to plan implant placements with a precision that was unimaginable a decade ago. Old methods like basic impressions and static X-rays, which led to approximate guesses about implant placement, are outdated.

The Future of Dental Implants in the Digital Age

A mere ten years back, the procedure for dental implants was predominantly manual, involving traditional putty for impressions, 2D X-rays, and a largely guesswork-based process. However, recent technological advances have transformed this practice, moving away from the previous trial-and-error method.

In current times, dental implants are at the forefront of a digital revolution, significantly reducing uncertainties and enhancing reliability for both patients and dental professionals.

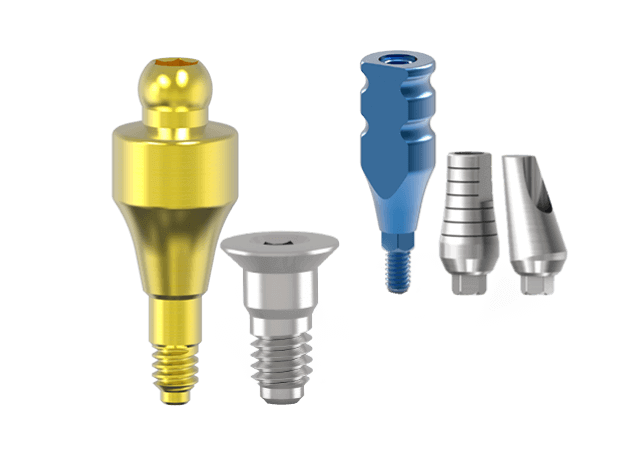

Micro-Movements of Implant-Abutment-Interface

In order to examine the existence of a micro gap in dental implants; a special experimental test field was developed.

For each type of implant system tested; five inspection pieces were manufactured. Each inspection piece simulates an implant-supported

molar crown in the upper jaw. During the load, in a two-dimensional chewing simulator, a constant and diverging X-ray device radiated the inspection pieces.

By transforming of the x-ray into visible light; x-ray videos were recorded, using a high-speed digital camera.

The results will give information on the development and a conclusion of a micro gap at the implant-abutment interface.

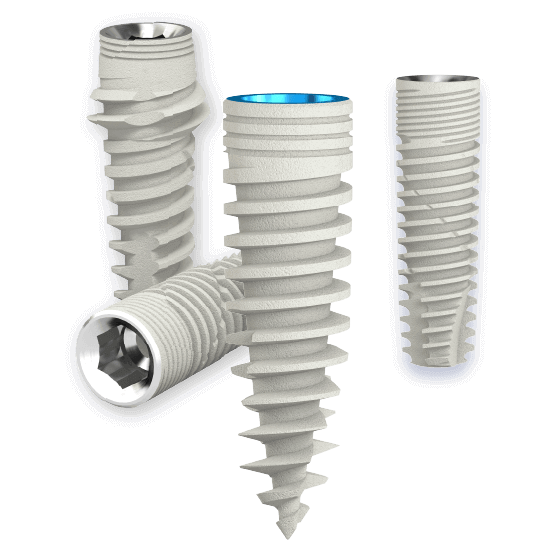

The Saturn immediate load post-extraction dental implant

The desire for immediate load restoration of dental implants, particularly in the anterior esthetic zone, requires specific implant design strategies to enhance primary stability.

In the presence of extraction sites, often with compromised bone, implant fixation is obtained apically and palatally.

The macro architectural design of the implant establishes an initial mechanical focus, which is crucial in minimizing implant mobility in the first 3-4 weeks of function.

Effects of Aging Torque Controllers on Screw Tightening Force and Bacterial Micro-Leakage on the Implant

A new study led by Prof. Zeev Ormianer evaluated the effects of aging torque controllers on screw tightening force and bacterial micro-leakage on the implant-abutment complex.

The study evaluated spring-type, friction-type torque controllers and IAC with both conical and hexagonal connections, applying chemical, mechanical, temperature, and pressure-aging methods.

The results of the study, recently published in the journal, MDPI, demonstrate a significant decrease in torque after 10 days of aging.

Digital implant entering the U.S. market

As a global leader in fully digital implant technology, the company, founded by a multinational consortium of dentists, surgeons, and engineers, combines innovative implant designs with a digital interface that takes the guesswork out of planning and placing implants.

Digitalization of the Golden Standard of Implantology.

In the last decade, the world has been going through rapid digitalization upgrading.

Most of the exciting conventional technologies no longer exist and were replaced by smart digital systems, which led them to another level of work-flow, abilities, and final results.

Those systems allow the users to have more available and accessible updated information, that will provide the most efficient workflow, accurate and easy planning, and predictable outcomes.

Comparison of Bone-to-Implant Contact and Bone Volume Around Implants Placed With or Without Site Preparation.

In order to examine the existence of a micro gap in dental implants; a special experimental test field was developed.

For each type of implant system tested; five inspection pieces were manufactured. Each inspection piece simulates an implant-supported

molar crown in the upper jaw. During the load, in a two-dimensional chewing simulator, a constant and diverging X-ray device radiated the inspection pieces.

By transforming of the x-ray into visible light; x-ray videos were recorded, using a high-speed digital camera.

The results will give information on the development and a conclusion of a micro gap at the implant-abutment interface.