In the field of dental implantation, accuracy is crucial for success. Recent technological advancements have revolutionized this area. Today, digital systems enable dentists to plan implant placements with a precision that was unimaginable a decade ago.

Old methods like basic impressions and static X-rays, which led to approximate guesses about implant placement, are outdated. Now, we have entered a new phase of precise surgical planning with submillimeter accuracy. This shift marks the digital revolution in implant planning.

Building a Detailed Digital Model of the Patient

The process begins with creating an extensive digital model of the patient’s oral anatomy. Instead of traditional dental putty, an intraoral scanner is used to capture exact details of the teeth and gums. This digital model is then combined with a CBCT scan, which reveals internal structures like sinus cavities, nerve pathways, and bone density that are invisible to the naked eye.

Merging these two data sets results in a detailed 3D virtual model of the patient, offering invaluable insight for precise implant placement.

Digital Practice of Implant Surgery

The core of this process involves specialized software for implant planning, where dentists can experiment with implant placement in a 3D digital environment. The software employs advanced algorithms to identify suitable locations in the jawbone, considering factors like bone depth and density.

Dentists can test different arrangements, taking into account aesthetics, bone preparation, and other considerations. This process allows for adjustments in implant size, position, depth, and angle until the ideal plan is achieved. This plan can then be used to guide actual computer-aided implant surgery

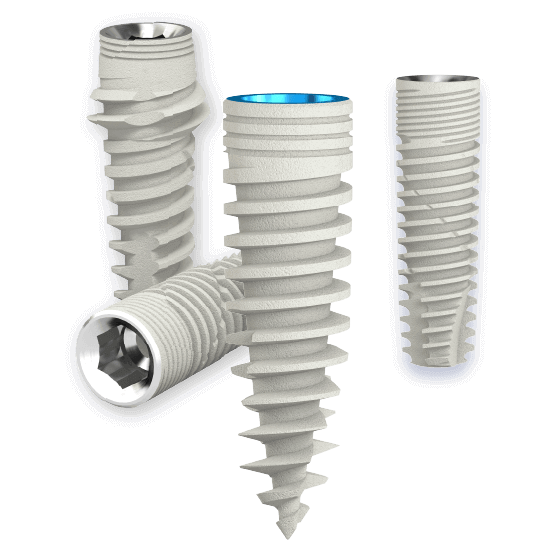

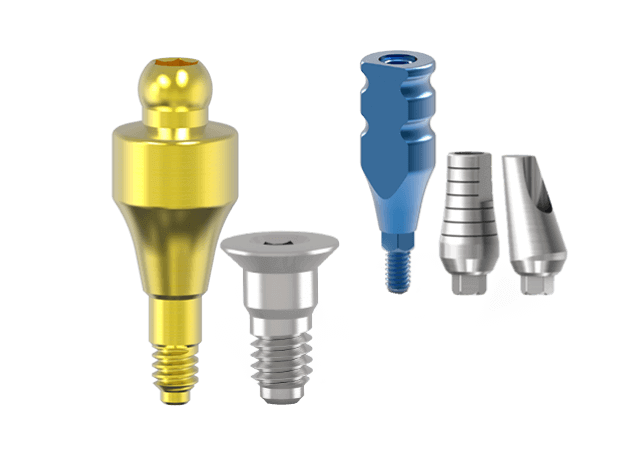

Personalized Dental Components

Digital technology greatly enhances customization, allowing for the creation of patient-specific dental components. Intraoral scans are used in design software to create tailored abutments, drill guides, and crowns well in advance of the surgery. These components are then 3D printed to ensure a perfect fit and immediate functionality.

Speeding Up the Process

By extensively planning and customizing beforehand, post-surgery care is expedited. With pre-determined implant locations, pre-designed surgical tools, and pre-made prosthetics, most of the work is completed before the patient arrives at the clinic.

This approach minimizes the number of dental visits and eliminates long waits for temporary components. In some cases, it even allows for the placement of final implants on the same day.

The Advantage of Complete Digital Clarity

By creating a comprehensive digital model for thorough pre-surgery planning, dental teams can carry out implant procedures with greater confidence, accuracy, and efficiency. The outcomes are more predictable, components fit seamlessly, and the entire process is sped up by the preparatory work done digitally.

The era of digital dental implants has begun, offering clearer and more precise outcomes for both dental professionals and patients.