Abstract

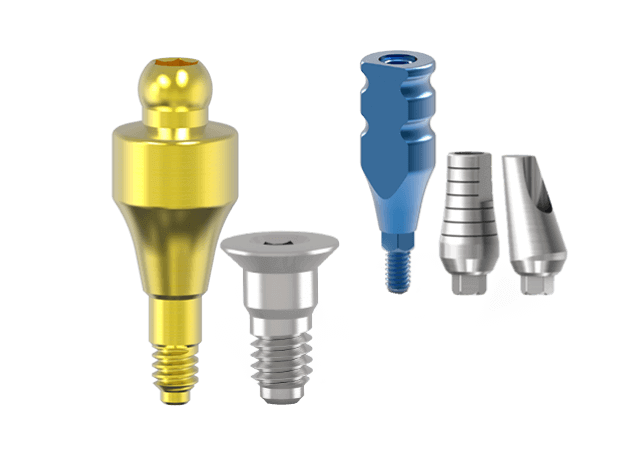

Aim: We assess the accuracy of torque controllers after several aging processes and the bacterial leakage on implant–abutment complexes (IAC).Methods: A total of 12 spring-type and 12 friction-type torque controllers and 48 IAC (24 conical and 24 hexagonal connections) were evaluated. Chemical, mechanical, temperature, and pressure-aging methods were applied individually to replicate clinical use. Torque controller accuracy was analyzed before and after aging using a calibrated gauge. To assess bacterial leakage, the IAC were suspended in a bacterial medium for 24 h.

Direct Contact Test (DCT) and Polymerase Chain Reaction Test (RT-PCR) analyzed the infiltration of F. nucleatum and P. gingivalis into the IAC micro-gap. Results: A significant decrease in torque after 10 days of aging was found. The spring-type torque controller was affected the most, regardless of the aging method (P < 0.05). PCR results indicated that all groups exhibited significantly more bacterial leakage, regardless of the method used (P < 0.05). The conical IAC demonstrated more

bacterial leakage of P. gingivalis compared with the hexagonal IAC (P = 0.07). DCT found bacterial growth in the IAC only before aging and was not identified after aging. Conclusion: Aging affects torque accuracy.

A reduction in force was noticed after 10 days. The conical IAC exhibits more bacterial leakage, although this was not statistically significant.

Keywords: torque; torque controller; sterilization; bacteria penetration, bacterial leakage on implant

Introduction to bacterial leakage on implant

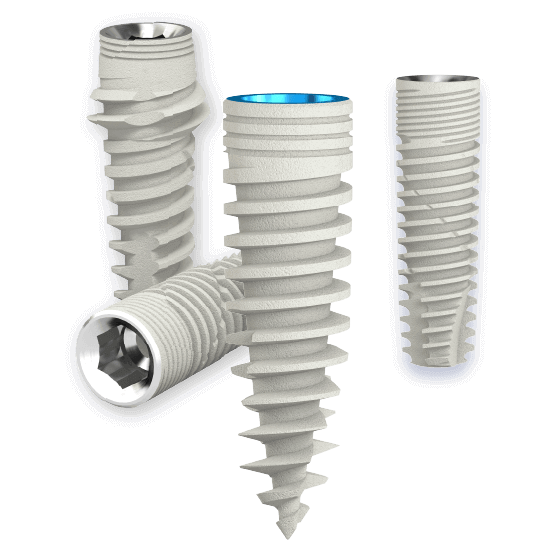

Dental implants are a common solution for edentulous ridges. Unintentional loosening of the implant/abutment complex is a frequent problem related to dental implants

[1,2]. To avoid complications, it is important to use controlled torques for fixating abutments on implants [3]. Applying torque to the abutment screw complex generates a tension force known as preload on the screw [4]. Under-torquing the screw joint causes dynamic fatigue and greater micro-motion at the implant–abutment junction, resulting in failure and loss of function [5]. The maximum torque that can be applied on the implant–abutment screw is up to 120% of the torque recommended by the manufacturer [6]. Over-torquing can lead to screw deformation, thread stripping, screw loosening, and fracture [4,6,7].

Inaccurate torque can be applied to the fastening screws because of device condition, frequency of use, debris in the operating mechanism, and possible corrosion [8,9].

Mechanical torque controllers (MTC) have several designs, among them are coil design, toggle design, and spring design.

The accuracy of the devices is within 10% of the target torque [10]. Therefore, torque-limiting devices, particularly friction-style devices, should be checked and calibrated during clinical use [10,11].